FLOW MASTER SEALS

Precision and Reliability in Every Seal

efficiency and reliability

Flow Master Seals

At Flow Master Seals, we specialize in delivering high-performance mechanical seals designed to meet the rigorous demands of various industrial applications.

Our seals are engineered to prevent leaks, reduce friction, and extend the lifespan of your equipment, ensuring optimal efficiency and safety.

With a commitment to quality and innovation, Flow Master Seals provides solutions that enhance productivity and minimize downtime. Trust Flow Master Seals for unmatched durability and reliability in every seal.

Flow Master Seals offers high-performance mechanical seals known for their durability, reliability, and efficiency. These seals are designed to prevent leaks, reduce friction, and extend equipment lifespan in various industrial applications.

High-performance

Flow Master Seals are designed to deliver exceptional performance in demanding industrial environments.

Durability

The seals are engineered to withstand harsh conditions and provide long-lasting service.

Reliability

Flow Master Seals are known for their dependability and consistency in preventing leaks and reducing friction.

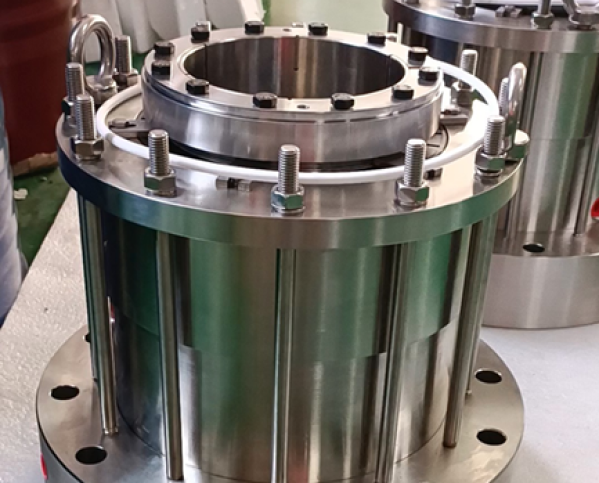

FMS - Liquid-Lubricated Seals

Product Overview:

Flow Master Seals’ liquid-lubricated seals are designed for top-entry drives, providing reliable sealing solutions for a variety of industrial applications. These seals are engineered to handle high pressures and rotating speeds, ensuring optimal performance and longevity.

Operating Range:

– Shaft Diameter: 40 mm to 220 mm (1.57″ to 8.66″)

– Pressure: Vacuum to 16 bar (232 PSI), with a maximum of 18 bar (261 PSI)

– Temperature: -40°C to +200°C (-40°F to +392°F), up to 350°C (662°F) with cooling flange

– Sliding Velocity: 0 to 5 m/s (0 to 16 ft/s)

Materials:

– Seal Faces: Carbon graphite or Silicon carbide, compliant with FDA standards

– Seats: Silicon carbide, compliant with FDA standards

– Secondary Seals and Metallic Parts: Customized according to application requirements

Standards and Approvals:

– FDA Compliant

– DIN Standards: DIN 28138, DIN 28136 T2, DIN 28141, DIN 28154

Applications:

– Refining Technology

– Petrochemical Industry

– Chemical Industry

– Pharmaceutical Industry

– Food and Beverage Industry

– Agitators and Reactors

Optional Features:

– Cooling/Heating Flange

– Leakage Drain

– Flush and Polymerization Barrier

Advantages:

– High Performance: Capable of operating at higher pressures and speeds than standard specifications.

– Versatile: Suitable for both stepped and unstepped shafts.

– Durable: Designed to withstand extreme conditions and ensure long-term reliability.

FMS - Dry Gas Seal

Product Overview:

Dry gas seals are non-contacting, dry-running mechanical face seals that consist of a rotating ring and a stationary ring. These seals use a fluid-dynamic lifting force to create a gap between the rings, ensuring minimal contact and wear. They are ideal for high-speed applications in industries such as oil and gas, petrochemical, and gas processing, where contamination and lubrication are concerns.

Key Features:

– Non-Contact Design: Utilizes a thin gas film to prevent contact between the seal faces, reducing wear and extending seal life.

– High Efficiency: Minimal leakage of sealing gas, ensuring efficient operation.

– Low Power Consumption: Requires less power for operation compared to traditional wet seals.

– Self-Cleaning: The gas film helps to keep the seal faces clean, reducing maintenance needs.

– High Reliability: Designed for long-term, reliable operation in demanding environments.

Operating Range:

– Pressure: Often up to 100 bar (1450 PSI) or more.

– Temperature: from -40°C to +200°C (-40°F to +392°F).

– Speed: Capable of operating at high rotational speeds, often up to 50 m/s (164 ft/s).

Materials:

– Seal Faces: Silicon carbide or tungsten carbide for durability and resistance to wear.

– Secondary Seals: Viton or PTFE, depending on the application requirements.

– Metal Parts: Stainless steel or other corrosion-resistant alloys to withstand harsh operating conditions are available.

Standards and Approvals:

– API 692: Compliance with the American Petroleum Institute standards for dry gas seals.

– ISO 10439: International standards for centrifugal compressors and their dry gas seals.

– ATEX Certification: For use in explosive atmospheres, ensuring safety and reliability.

Applications:

– Oil and Gas Industry

– Petrochemical Plants

– Refineries

– Pipelines

– Offshore Platforms

Advantages:

– Elimination of Sealing Oil System: Reduces the complexity and maintenance associated with oil-based seals.

– Prevents Contamination: No risk of oil contaminating the process gas.

– Reduced Maintenance Costs: Lower unplanned maintenance and downtime.

– Improved Safety: Eliminates risks associated with oil-based systems, such as oil blowouts.

– Environmental Benefits: Minimal leakage and no oil contamination contribute to a cleaner environment.

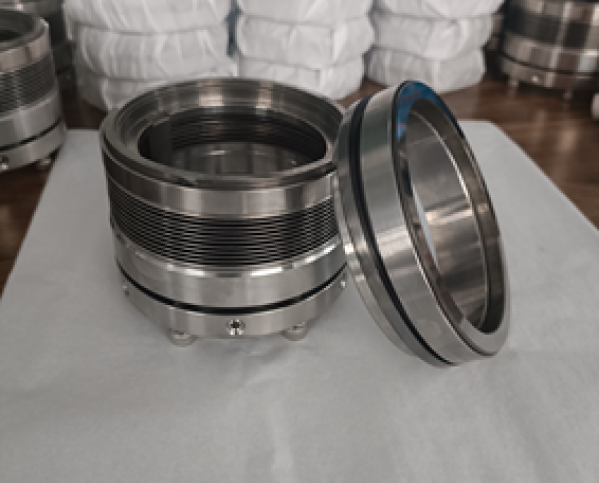

FMS - Metal Bellow Seal

Product Overview:

Metal bellow seals are designed with a flexible metal bellow that acts as a secondary sealing element and spring mechanism. This design allows for effective sealing in high-temperature and high-pressure environments. Metal bellow seals are commonly used in chemical processing, oil refining, and other demanding applications where conventional seals may fail.

Key Features:

– Non-Pusher Design: Eliminates dynamic O-rings, reducing the risk of clogging and wear.

– Edge-Welded Bellows: Provides high strength and flexibility, allowing for greater axial, angular, and radial movements.

– High-Temperature Capability: Suitable for extreme temperature applications.

– Corrosion Resistance: Made from materials that resist corrosion, ensuring long-term reliability.

– Compact Design: Ideal for applications with limited space.

Materials:

– Bellows: Stainless steel, Inconel, Hastelloy, or other high-performance alloys.

– Seal Faces: Silicon carbide or tungsten carbide for durability and wear resistance.

– Secondary Seals: Viton or PTFE, depending on the application.

– Metal Parts: Stainless steel or other corrosion-resistant alloys.

Operating Range:

– Pressure: Up to 50 bar (725 PSI) or more.

– Temperature: from -40°C to +400°C (-40°F to +752°F).

– Speed: Up to 25 m/s (82 ft/s).

Standards and Approvals:

– API 682: Compliance with the American Petroleum Institute standards for mechanical seals.

– ISO 21049: International standards for mechanical seals.

– ATEX Certification: For use in explosive atmospheres, ensuring safety and reliability.

Applications:

– Oil and Gas Industry

– Chemical Processing

– Pharmaceutical Industry

– Power Generation

– Aerospace

Advantages:

– Long Service Life: Designed to withstand extreme conditions and provide long-term reliability.

– Maintenance-Free: Non-pusher design reduces the need for regular maintenance.

– High Performance: Capable of operating at higher pressures and temperatures than standard seals.

– Versatile: Suitable for a wide range of applications and environments.

– Environmental Benefits: Minimal leakage and no oil contamination contribute to a cleaner environment.

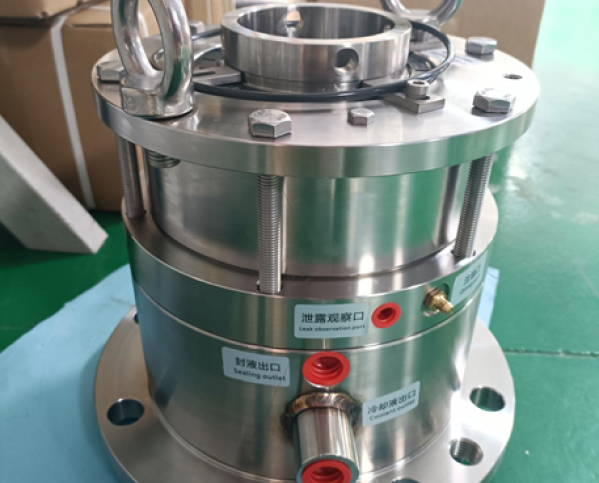

FMS - Mixer and Agitator Seal

Product Overview:

Mixer and agitator seals are specifically engineered for use in mixers, agitators, and reactors. These seals are designed to handle the radial and axial shaft movements typical in such equipment. They can operate in wet, dry, or gas-lubricated conditions, making them suitable for industries like chemical, pharmaceutical, and food processing.

Key Features:

– Robust Design: Engineered to handle the unique challenges of mixing and agitating processes, including high radial and axial movements.

– Multiple Seal Configurations: Available in single, double, and tandem configurations to suit various application needs.

– Cartridge Design: Simplifies installation and maintenance, reducing downtime.

– Self-Cleaning: Designed to prevent product buildup and ensure consistent performance.

– High Efficiency: Provides reliable sealing with minimal leakage.

Materials:

– Seal Faces: Silicon carbide or tungsten carbide for durability and wear resistance.

– Bellows: Stainless steel, Hastelloy, or other high-performance alloys.

– Secondary Seals: Viton or PTFE, depending on the application.

– Metal Parts: Stainless steel or other corrosion-resistant alloys.

Operating Range:

– Pressure: Up to 25 bar (362 PSI) or more.

– Temperature: from -40°C to +200°C (-40°F to +392°F).

– Speed: Up to 20 m/s (66 ft/s).

Standards and Approvals:

– API 682: Compliance with the American Petroleum Institute standards for mechanical seals.

– ISO 21049: International standards for mechanical seals.

– ATEX Certification: For use in explosive atmospheres, ensuring safety and reliability.

Applications:

– Chemical Processing

– Pharmaceutical Industry

– Food and Beverage Industry

– Mining and Ore Processing

– Water and Wastewater Treatment

Advantages:

– Long Service Life: Designed to withstand extreme conditions and provide long-term reliability.

– Maintenance-Free: Non-pusher design reduces the need for regular maintenance.

– High Performance: Capable of operating at higher pressures and temperatures than standard seals.

– Versatile: Suitable for a wide range of applications and environments.

– Environmental Benefits: Minimal leakage and no oil contamination contribute to a cleaner environment.

FMS - Single Cartridge Mechanical Seal

Product Overview:

Single cartridge mechanical seals are pre-assembled, self-contained units that simplify installation and maintenance. They consist of multiple components, including a stationary part fixed to the equipment casing and a rotating part attached to the shaft. These seals are ideal for preventing fluid leakage in pumps, mixers, and other rotating equipment. Their design ensures reliable performance and ease of use, making them a popular choice in various industries.

Key Features:

– Pre-Assembled Unit: Simplifies installation and reduces the risk of installation errors.

– Balanced Design: Ensures stable operation and reduces wear on seal faces.

– Integrated Gland Plate: Provides proper alignment and structural integrity.

– Single Seal Face: Suitable for general-purpose applications, offering a basic level of protection.

– Flush, Quench, and Throttle Options: Available with various configurations to suit different operational needs.

Materials:

– Seal Faces: Silicon carbide, tungsten carbide, or carbon for durability and wear resistance.

– Secondary Seals: Viton, EPDM, or PTFE, depending on the application.

– Metal Parts: Stainless steel or other corrosion-resistant alloys.

Operating Range:

– Pressure: Up to 25 bar (362 PSI) or more.

– Temperature: From -40°C to +200°C (-40°F to +392°F).

– Speed: Up to 20 m/s (66 ft/s).

Standards and Approvals:

– API 682: Compliance with the American Petroleum Institute standards for mechanical seals.

– ISO 21049: International standards for mechanical seals.

– ATEX Certification: For use in explosive atmospheres, ensuring safety and reliability.

Applications:

– Chemical Processing

– Pharmaceutical Industry

– Food and Beverage Industry

– Water and Wastewater Treatment

– General Industrial Applications

Advantages:

– Ease of Installation: Pre-assembled design reduces installation time and errors.

– Cost-Effective: Offers considerable cost savings compared to more complex seal designs.

– Reliable Performance: Balanced design and high-quality materials ensure long-term reliability.

– Low Maintenance: Reduces the need for frequent maintenance and associated downtime.

– Environmental Benefits: Minimal leakage and no oil contamination contribute to a cleaner environment.

FMS - Dual Cartridge Mechanical Seal

Product Overview:

Dual cartridge mechanical seals feature two independent seals within a single cartridge unit, providing enhanced reliability and safety. These seals are ideal for handling hazardous, abrasive, or corrosive liquids, as they ensure clean lubrication and extended seal life. They are commonly used in industries such as oil and gas, chemical processing, and slurry applications. The dual seal configuration offers superior protection against leaks and contamination.

Key Features:

– Dual Seal Configuration: Provides enhanced leak prevention with a secondary seal as an additional barrier.

– Balanced Design: Ensures stable operation and reduces wear on seal faces.

– Cartridge Unit: Pre-assembled for easy installation and maintenance.

– Independent of Rotation Direction: Suitable for applications regardless of the direction of rotation.

– Integrated Pumping Device: Enhances fluid circulation and cooling.

Materials:

– Seal Faces: Silicon carbide, tungsten carbide, or carbon for durability and wear resistance.

– Secondary Seals: Viton, EPDM, or PTFE, depending on the application.

– Metal Parts: Stainless steel or other corrosion-resistant alloys.

Operating Range:

– Pressure: Up to 25 bar (362 PSI) or more.

– Temperature: From -40°C to +220°C (-40°F to +428°F).

– Speed: Up to 20 m/s (66 ft/s).

Standards and Approvals:

– API 682: Compliance with the American Petroleum Institute standards for mechanical seals.

– ISO 21049: International standards for mechanical seals.

– ATEX Certification: For use in explosive atmospheres, ensuring safety and reliability.

Applications:

– Chemical Processing

– Pharmaceutical Industry

– Food and Beverage Industry

– Water and Wastewater Treatment

– General Industrial Applications

Advantages:

– Enhanced Leak Prevention: The secondary seal provides an additional barrier against leakage, making it ideal for hazardous or environmentally sensitive fluids.

– Ease of Installation: Pre-assembled design reduces installation time and errors.

– Reliable Performance: Balanced design and high-quality materials ensure long-term reliability.

– Low Maintenance: Reduces the need for frequent maintenance and associated downtime.

– Environmental Benefits: Minimal leakage and no oil contamination contribute to a cleaner environment.

Special Mechanical Seal

Special mechanical seals are customized solutions designed to meet unique application requirements. These seals can be tailored to handle extreme temperatures, pressures, and aggressive media, providing reliable performance in challenging environments. They are used in a variety of industries, including aerospace, marine, and specialized manufacturing. These bespoke seals ensure optimal functionality and durability for specific operational needs.

Special Mechanical Seal operation limits

1- Temperature Range: Varies based on customization, typically up to 400°C

2- Pressure Range: Varies based on customization, typically up to 40 bar

3- Speed Varies based on customization, typically up to 30 m/s

*These limits can vary depending on the specific design and application requirements. If you need more detailed information or have specific conditions request please don’t hesitate to contact us.

Learn more

Frequently Asked Questions