OCTG - API 5CT

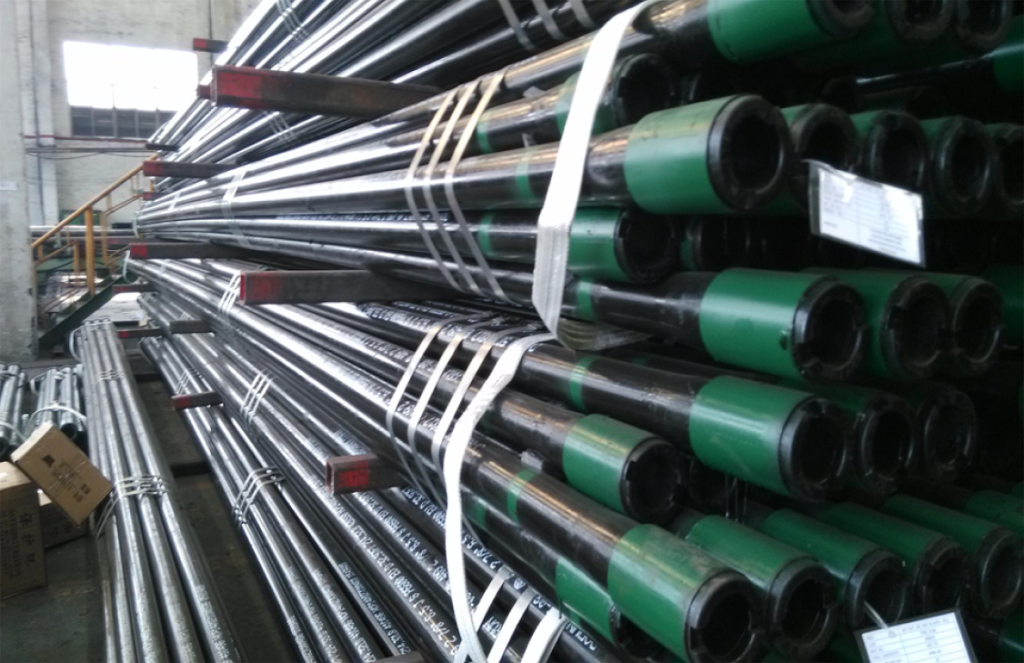

Oil Country Tubular Goods (OCTG). These seamless rolled products play a crucial role in the oil and gas industry

traceability

Oil and gas industry

OCTG stands for «Oil Country Tubular Goods». It refers to a group of seamless and welded steel pipes used primarily in the oil and gas industry .

OCTG refers to three primary products:

1. Drill Pipe: Heavy seamless tubes that rotate the drill bit and circulate drilling fluid during drilling operations.

2. Casing: Pipes that line the borehole, exposed to axial tension and internal pressure from pumped oil and gas emulsion.

3. Tubing: Pipes through which gases and oils are transported from the wellbore.

Market Trends:

– Increased Drilling Operations: OCTG usage is rising due to deep-water exploration and onshore oil field development. – Hydraulic Fracturing and Horizontal Drilling: These technologies drive demand for OCTG.

– Seamless Pipes: Their uniform shape and high-pressure resistance contribute to market growth.

– Exploration and Production Activities: Government initiatives and E&P efforts support OCTG demand.

OCTG - Oil Country Tubular Goods Key Features

- Material: OCTG is manufactured from alloy steel or carbon using electric resistance welded (ERW) or seamless processes. - Application: They are essential for drilling, equipment, and well operation in oil and gas production. - Global Market: The global OCTG market size reached US$ 24.5 billion in 2023 and is projected to grow to US$ 40.7 billion by 2032, exhibiting a 5.7% CAGR.

Casing Pipes

Lines the inside of the wellbore to strengthen the well after drilling and protects the it from contaminants.

Tubing Pipes

Installed after the casing to facilitate the extraction of hydrocarbons from the reservoir.

Drill Pipes

Used to transmit drilling fluid and torque from the surface to the drill bit, providing structural support during drilling and exploration.

Commitment

Let's dive into the specifics of API 5CT casing and Tubing pipes:

Casing Pipe

Casing pipe dimensions range from: 4-1/2 inches to 20 inches in diameter.

Grades: API 5CT specifies various steel grades for casing pipes, including J55, K55, N80, L80, P110, and more.

– Each grade has distinct mechanical properties, corrosion resistance, and suitability for specific well conditions.

Thread Types:

– BTC (Buttress Thread): Commonly used for casing connections.

– LTC (Long Thread): Suitable for both casing and tubing.

– STC (Short Thread): Used for tubing connections.

– Premium Connections: High-performance threads with enhanced sealing and load-bearing capabilities.

– HYD (Hydraulic): Used in specific applications.

Test: According to API 5CT standard

Packing: by bundle

Tubing Pipe

Tubing dimensions span from: 1.050 inches to 4-1/2 inches.

Grades: API 5CT specifies various steel grades for casing pipes, including J55, K55, N80, L80, P110, and more.

Thread Types:

– EUE (External Upset End)

– NU (Non-Upset End)

Test: According to API 5CT standard

Packing: by bundle

API 5CT Premium Connection

Standard: API SPEC 5CT SPEC 5B

OD: 2-3/8” TO 20”

WT: 4.24mm to 16.13mm

Material: J55 K55 N80 L80 C90 T95 P110,1CR%, 3CR%,9CR%,13CR%

Level: PSL-1, PSL-2 and PLS-3

T&C: TG-QMI, TTSP-1, TTSP-2, TTSP-3, TTSP-4

Length: R1, R2, R3

Test: Pipe according to API

Packing: Loose, bundle or pallet

Casing & Tubing Couplings

Standard: API 5CT & 5B

Steel Grade: H40,J55, K55, N80, R95,L80, C90, T95, P110, Q125

Dimension: Tubing coupling from 2-3/8″ to 4-1/2″; Casing coupling from 4-1/2″ to 20″

End finish: NUE, EUE (tubing coupling); STC, LTC, BTC (casing coupling)

Colors: J55/ K55-Bright Green, P110-White, N80/ L80-Red and more.

Packing: by wooden cases, wooden pallet, or as per customer request

API Pup Joints

Slotted Liner

Slotted liners are made from tubulars by saw-cutting slot configurations. Slot widths are often referred to in terms of gauge. Slot or screen gauge is simply the width of the opening in inches multiplied by 1000. For instance, a 12-gauge screen has openings of 0.012 in.

Specification

Learn more

Frequently Asked Questions